Flight control systems that lead commercial aviation

We’ve been improving flight controls for 40+ years, with an installed base of 15,000 aircraft. Our fly-by-wire controls – the first in commercial aircraft – continue to make flight more agile, secure, and affordable. And our advances in autonomous controls and electric aircraft will further transform aviation.

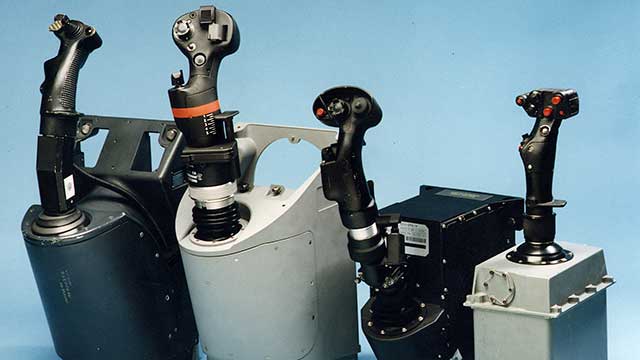

Every second of the day, an aircraft somewhere in the world takes off enabled by flight-critical systems designed, produced, and supported by BAE Systems. Our advanced, fly-by-wire (FBW) control systems are the operational heart of those aircraft, including our primary flight control computers (FCC), our active inceptor systems (AIS) and active control sticks (ACS), our slat & flap electronic control units (SFECU) and spoiler control electronics (SCE), our actuator control electronics (ACE), and our remote electronics units (REU). Whatever the nature of your aviation mission – manned or autonomous – no one delivers more advanced, high performance flight control solutions for your aircraft than BAE Systems.

See a more detailed list of our flight controls portfolio for commercial aircraft below, as well as key features and capabilities of our integrated flight control system elements. Contact our commercial aircraft solutions electronic systems director of business development today to learn more.

A comprehensive portfolio of flight controls for fixed-wing and rotary commercial aircraft

- Primary flight controls, including fly-by-wire systems

- Secondary/slat and flap (high lift) flight controls and monitoring

- Actuator control electronics

- Remote electronics units

- Rudder and yaw control

- Stabilizer control and monitoring

- Spoiler control electronics and monitoring

- Active inceptor systems (AIS)

- Digital FBW control systems

- Optionally-manned / autonomous flight control systems

- Autopilot controls

- Ground collision avoidance systems

- Rate and acceleration sensors

- Vehicle management systems / computers

- Prognostics and health management

Learn more about our Flight control products

BAE Systems is proud to offer our customers and partners a broad portfolio of advanced stick-to-surface flight control avionics designed with performance and safety in mind.

FCC Capabilities

- Primary flight control computers (FCC) – sometimes referred to as primary flight control electronics (FCE) – are located in the aircraft electronic equipment (EE-Bay)

- There are typically three redundant FCCs installed on an airplane

- The FCC computes and transmits all primary surface actuator commands (rudder, elevators, ailerons, flaperons, and horizontal stabilizer) to control and maintain normal flight

- FCCs are designed to provide full flight functions

- The FCC also performs pre-flight functions to verify the electronics dispatch integrity, as well as ground maintenance functions

Data interface capabilities

- ARINC gateways

- Data concentration and distribution

- Flight data acquisition

Also referred to as high lift or secondary flight controls, slat & flap electronic control units (SFECUs) enable optimum take-off and landing speeds by increasing wing lift.

Capabilities

- The SFECU is installed in the equipment bays in the body of the aircraft

- The SFECU controls the slats and flaps (on the wings) utilized during take-offs and landings

- Primary purpose of the slats and flaps is to make the area of the wing bigger, thus enabling the aircraft to fly more slowly

- The slats and flaps do not make the aircraft fly more slowly, they increase lift which enables the pilot to control the speed

- Slats and flaps are extended and retracted, whereas the spoilers are raised and lowered

Part of our flight-critical fly-by-wire (FBW) system, the actuator control electronics (ACE) issue the commands that cause the aircraft’s control surfaces to move and keep it on the desired flight path.

Capabilities

- Actuator control electronics are located in the aircraft electronic equipment bay (EE-Bay)

- ACEs either directly or indirectly control (via remote electronics units) an aircraft’s primary flight-critical surface (rudder, elevators, ailerons, flaperons, and horizontal stabilizers) as well as the multi-functional spoilers and ground spoilers to control and maintain normal flight

- ACEs work with the primary flight control computers (FCCs), to provide all normal flight control modes and handling qualities

Remote electronics units (REU) are distributed electronics that reside close to or are mounted on the actuator to provide local control of the actuator. The REU receives commands and processes incoming and outgoing signals for the functions necessary to control the actuators.

Capabilities

- An REU may control one or more hydraulic or electro-mechanical actuators. In event of a flight control computer failure, REUs can take over primary control of the aircraft surfaces

- REUs include redundant lanes within a channel to ensure the integrity of actuator commands

- The number of REUs needed on an aircraft depends on the flight control system architecture

- Our REUs weigh between one and four pounds each, depending on the functionality they offer. All REUs are designed for non-pressurized, in-wing applications